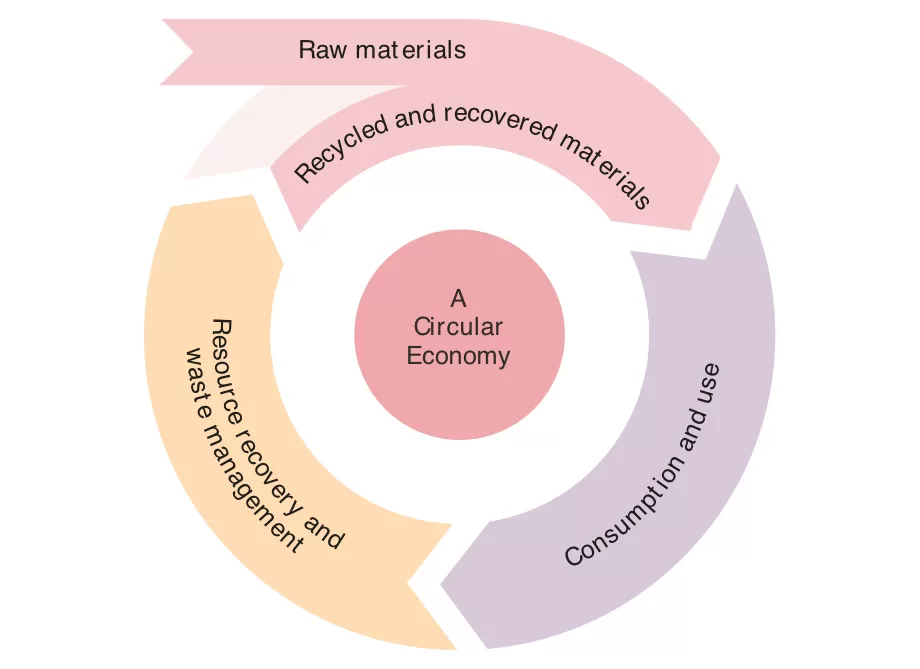

What is the Circular Economy

The Circular Economy is a transformative approach to our conventional, linear economic framework characterised by a ‘take, make, dispose’ model. In contrast, the Circular Economy promotes a cyclical model where resources are continually reclaimed, reused, and revitalised.

The primary objective of the Circular Economy is to drastically reduce material wastage. Rather than solely focusing on recycling, the Circular Economy emphasises the holistic reduction of resource consumption, waste generation, pollution, and greenhouse gas emissions.

Circular Economy, GOV.UK

Circular Economy, GOV.UK

At its core, the Circular Economy seeks to foster a self-sustaining system that offers multifaceted benefits, harmonising the interests of businesses, society, and the broader environment.

The Circular Economy concept is versatile and can be applied across industry. Sectors can contribute by changing their sourcing practices, redesigning products, and altering consumption patterns.

The Traditional Life Cycle of Consumption

The traditional life cycle of materials is linear, starting with extraction and ending with disposal, resulting in the depletion of finite natural resources and producing environmental pollution:

- The extraction phase involves sourcing raw materials from the earth, which often involves processes that can harm the environment.

- Following extraction, production sees raw materials transformed into products, consuming energy and generating emissions.

- The use phase serves their purpose, which for some could be decades, or just a single-use.

- Finally, the disposal stage ends up in landfills or incineration.

Breaking this cycle is not only beneficial for the environment, but it also presents economic opportunities in innovation and sustainable technology. By transitioning to a Circular Economy, materials can be in circulation for an extended period, minimising waste and environmental degradation.

The Importance of the Circular Economy

The concept of a Circular Economy is gaining more and more attention, and for good reason; keeping resources in use for as long as possible and extracting the maximum value from them before recovering and regenerating them makes a lot of sense, and can bring increased resource efficiency, better product design, and job creation.

Existing and upcoming UK legislation aimed at reducing waste.

The UK Government is committed to transitioning towards a Circular Economy, as reflected in its alignment with the Circular Economy Package (CEP). This revamped legislative framework focuses on a comprehensive approach to waste management and recycling, aiming to reduce waste and establish a long-term, sustainable path forward.

Several existing and upcoming legislations target waste reduction specifically within the construction sector:

Existing Legislation:

- Site Waste Management Plans (SWMPs): While SWMPs are no longer legally required in England, many construction firms still use them voluntarily. SWMPs outline how construction waste will be managed and how its volume will be reduced.

- The Landfill Tax Regulations: Introduced in 1996, this tax is levied on waste sent to landfill. The construction industry, producing a significant amount of waste, has been motivated to divert waste away from landfills due to this tax.

- The Aggregates Levy: A tax on sand, gravel, and rock that’s dug from the ground or dredged from the sea in UK waters, this levy encourages the recycling of construction materials.

- Construction Products Regulation (CPR): This mandates that construction products in the UK carry a CE mark, ensuring they comply with environmental standards.

Upcoming/Recent Legislation:

- Resource and Waste Strategy: Elements of the Resource and Waste Strategy focus on sustainable production and promote eco-friendly construction materials that are efficient to manufacture and have low environmental impacts.

- Net-Zero Carbon by 2050: While not exclusively waste-related, the commitment to achieve net-zero carbon emissions by 2050 will significantly influence the construction industry, from sourcing materials to waste management practices.

- Extended Producer Responsibility (EPR): Future EPR schemes might expand to cover construction products, making producers responsible for the entire lifecycle of their products, including end-of-life management.

- Green Building Standards: While existing standards like BREEAM and LEED encourage waste reduction, it’s anticipated that future regulations will place even greater emphasis on sustainable construction practices, including waste reduction.

- Reduced VAT on Green Products: The government has discussed reducing VAT on eco-friendly products. If implemented, this could encourage the construction industry to opt for sustainable materials, reducing waste.

The Pivotal role of Construction in the Circular Economy

The construction industry stands out as holding a critical role in promoting a Circular Economy, with the use of raw materials and significant waste generated, there is considerable opportunity for positive change in our industry.

By embracing circular principles, the construction industry can reduce its environmental impact, influence other industries through its extensive supply chain, and lead the way in developing innovative materials and waste management techniques that could be replicated across other sectors.

The significance of Minimising Resource use in Concretes, Aggregates and Steel

Natural aggregates, concrete, and steel are the backbone of the construction industry. They provide the foundational strength to numerous infrastructural elements that form the bedrock of modern civilization, but these account for a significant portion of the construction industry’s resource consumption.

Thankfully, our industry is not static. Innovations are continually being pursued to ensure a more sustainable approach. Some of the potential avenues are:

- Recycled Aggregates: By reusing aggregates from old construction projects, we can significantly reduce the need for new extraction. This not only conserves natural resources but also reduces the energy-intensive processing and transporting of virgin materials.

- Alternative Binders in Concrete: Researchers are exploring alternatives to traditional cement, which can reduce the carbon footprint of concrete production. Fly ash, slag, and natural pozzolans are some examples.

- Green Steel Production: Techniques like hydrogen-based steel production are being explored as cleaner alternatives to traditional methods, aiming to reduce CO2 emissions.

Immediate Benefits of Implementing Circular Economy Principles

As we continue to consume resources at an alarming rate, the pressure on the construction industry is mounting and the costs of using finite resources are increasing. The Circular Economy is a new way of thinking and whilst implementing these new practices may seem daunting, the potential benefits are immediate:

- Cost Savings: By reusing and recycling materials, construction firms can significantly reduce procurement costs. Given the rising prices of resources, this can offer immediate financial relief.

- Waste Reduction: The Circular Economy emphasises minimising waste. For construction, this translates to reduced disposal costs and more efficient use of materials, by leaving more of the ground untouched or reusing materials on-site.

- Resource Security: Relying on recycled and reused materials can shield construction firms from supply chain disruptions, ensuring consistent access to essential resources.

- Regulatory Compliance: As governments worldwide intensify their environmental regulations, adopting circular practices can ensure that construction firms remain compliant, avoiding potential fines or sanctions.

- Reduced Carbon Footprint: Using recycled materials and minimising waste can significantly reduce the construction industry’s carbon emissions, contributing to global climate change mitigation efforts.

- Long-term Sustainability: Moving to a Circular Economy ensures that the construction industry remains viable and profitable in the long run, safeguarding against resource scarcity and environmental degradation.

- Enhanced Brand Reputation: In a world increasingly conscious of sustainability, developers that adopt Circular Economy principles can bolster their brand image, appealing to eco-conscious clients and stakeholders.

- Access to New Markets: Adopting circular practices can open doors to new markets that prioritise sustainability, such as green building projects or eco-friendly infrastructure developments.

- Immediate ROI: The Circular Economy isn’t just about future-proofing. Immediate actions, like integrating recycled materials or optimising waste management processes, can offer rapid returns on investment.

We cannot afford to wait for a distant future where resources are even more scarce and expensive. The time to act is now, and by doing so, we can save on costs and create a more sustainable future.

How Established Accreditations are Integrating the Principles of the Circular Economy

BREEAM, LEED, and CEEQUAL are among the most well-recognised accreditations in the construction and infrastructure sectors. In response to the growing emphasis on sustainability, these accreditations have evolved to integrate and prioritise the principles of the Circular Economy.

BREEAM (Building Research Establishment Environmental Assessment Methodology) emphasises material efficiency, prioritising waste reduction and the use of sustainable and recycled materials.

Similarly, LEED (Leadership in Energy and Environmental Design) champions the reuse of existing structures, encourages the incorporation of sustainable materials, and rewards construction waste management that aligns with Circular Economy practices.

CEEQUAL (Civil Engineering Environmental Quality Assessment and Award Scheme) focusing primarily on civil engineering projects, underscores the importance of sustainable material use and efficient waste management.

All three accreditations have evolved to advocate for a holistic approach to sustainability, encompassing the entire project lifecycle from design to post-construction. Through their rigorous criteria, these accreditations are steering the industry towards practices that are not only environmentally responsible but also economically sound. Aligned with the industry, SPEEDECK provides innovative solutions for waste reduction, efficient resource utilisation, and environmental impact mitigation. Embracing the circular economy, we champion sustainable design and practices in foundation construction.

Circular Economy in Foundation Construction: Principles to Adopt

Circular Economy Principles for Construction

The Circular Economy’s hierarchy of material usage and circulation is a smart approach to reduce waste and maximise resources. This hierarchy, when applied to foundation construction, provides a framework for maximising the utility of materials and significantly curbing waste:

Maintain: Maintenance forms the frontline defence against wear and tear. Regular checks and routine upkeep to structural and geotechnical elements can preemptively address potential issues, maintaining integrity.

Re-use: The concept of reusing is integral to waste minimisation. Instead of viewing old foundations as obsolete, they can be viewed as pre-built bases for new constructions. When an old structure is razed, the existing foundation can be recalibrated to support new architectural designs, as long as it adheres to safety and structural standards.

Repair: Every crack or minor damage doesn’t necessitate a foundation overhaul. Often, timely repairs can restore a foundation’s functionality.

Repurpose: Design Engineering plays a pivotal role in the Circular Economy. If a foundation loses its primary utility, innovative thinking can envision alternative applications for its components.

Recycle: As a last resort, when a foundation or its elements have been exhausted of all functional possibilities, recycling offers an exit strategy that’s eco-friendly. Recycling ensures that the intrinsic value of the materials is not lost or contributing to emissions as heavily.

SPEEDECK believes the industry can make significant strides in sustainability through adopting these principles, ensuring each material’s maximum utility while perpetuating a cycle that keeps waste at a minimum and provides significant value.

The Critical Importance of Waste Reduction and Elimination

Waste provides constant challenges, and each discarded material represents not just a financial loss, but a missed opportunity to utilise resources efficiently. Environmentally, non-biodegradable construction waste threatens terrestrial and aquatic ecosystems, leading to soil degradation and water contamination. Economically, waste management incurs direct costs like landfill fees and indirect expenses, including transportation and potential legal penalties.

In foundation construction, waste can stem from surplus materials left unused, the repercussions of flawed construction necessitating costly reworks, to the dismantling of outdated foundations without considering recycling or repurposing possibilities.

The key to reducing waste lies in:

- Optimising designs, ensuring precise calculations and thorough understanding of the underlying ground model.

- Training construction teams for efficient and sustainable construction.

- Recycling and repurposing materials can include reusing ground, or implementing past structural elements into the foundation.

SPEEDECK’s Role in Advancing the Circular Economy in Construction

SPEEDECK plays a crucial role in advancing the Circular Economy by providing innovative solutions that tackle waste, improve resource efficiency, and reduce environmental impact. We are driving change by fostering sustainable design and construction practices that focus on closed-loop systems, waste reduction, and reuse of existing materials.

The Value of Detailed As-Built Records

Accurate and detailed records of a building’s structure are vital for any future renovations or alterations. That’s why SPEEDECK’s service includes providing detailed as-built records as standard.

These records allow for the sensible consideration of foundation re-use, which is especially important when looking to improve a building’s sustainability.

The records give a comprehensive overview of the building’s structural components, including any hidden features that may not be visible during visual inspections. Building owners and contractors can save valuable time and money in future renovations and upgrades with these records, ensuring the longevity and efficiency of the building’s foundation.

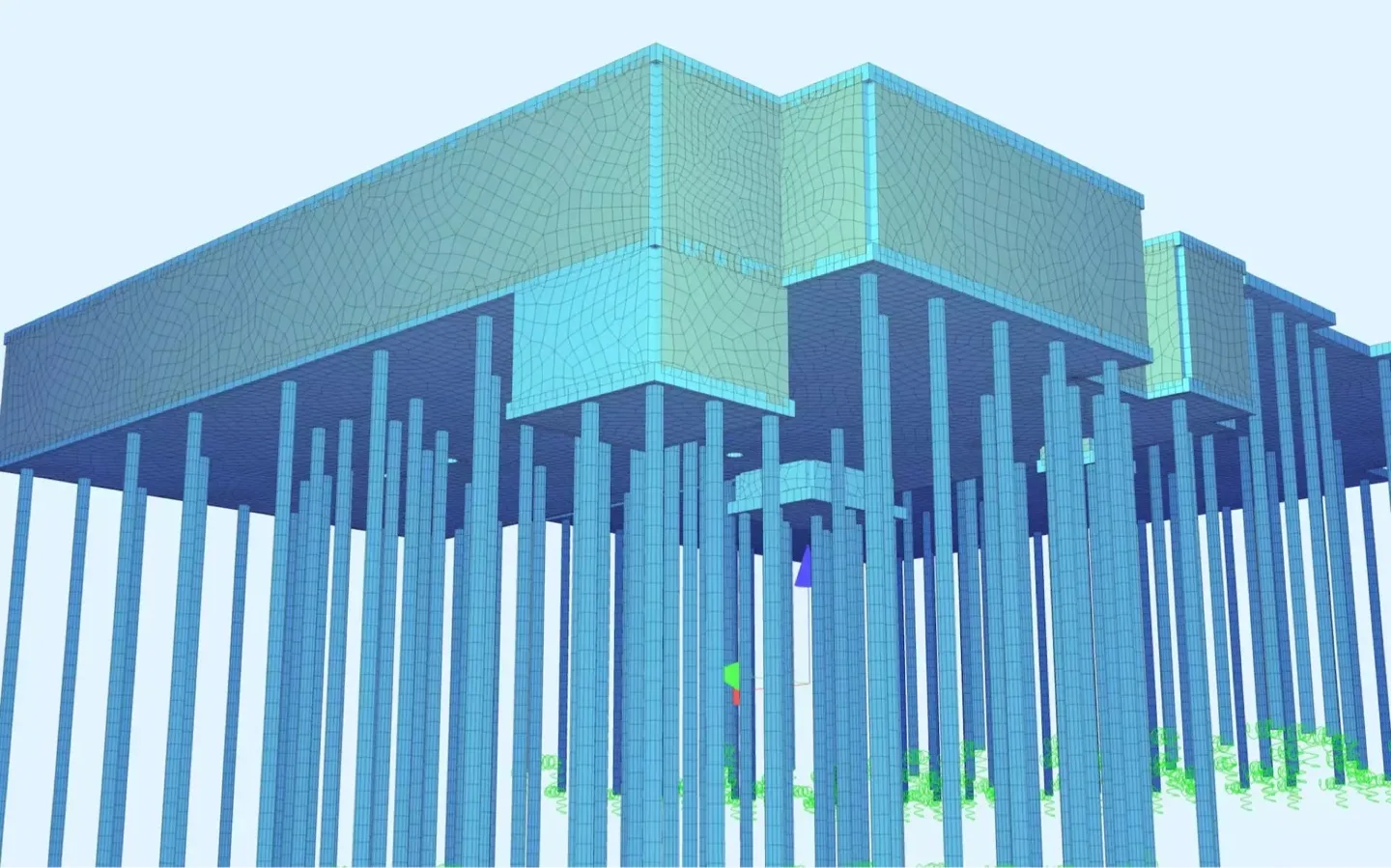

Design Optimisation to Reduce Concrete Usage

Design optimisation is key when it comes to reducing concrete usage and waste. Overall, SPEEDECK’s construction methods offer significant advantages in terms of concrete use and waste reduction:

- At SPEEDECK, we utilise smaller diameter CFA and driven piles. These methods keep pile numbers and lengths to a minimum, resulting in less total concrete usage compared to traditional piles.

- Our use of small diameter piles means less spoil arises during construction. We also often use driven piles, which don’t produce any arising spoil at all.

- When compared to mass fill foundations, our construction methods use less concrete.

- Our use of lightweight piling rigs also means we typically don’t require a piling mat, further reducing the amount of material needed on site.

- To reduce waste, we order materials efficiently, and our repeatable designs mean any surplus materials can easily be used elsewhere.

Use of low Carbon Concrete, Their Benefits and Sources

More attention is being given to low carbon concrete and their benefits. These concretes are made by reusing waste products from other industries, thereby reducing the amount of virgin materials needed and minimising waste.

By using low carbon concretes, we can help to reduce the environmental footprint of the construction industry and promote a more sustainable future.

These innovative materials can come from many sources, ranging from fly ash to biochar. With proper materials and processes, low carbon concretes can be produced on a large scale.

Reusing and Recycling Foundations

Recycling foundations is not an easy task, but reusing them holds a lot of potential – both economically and environmentally.

Disassembly of a foundation requires a lot of labour and energy, and recycling materials like concrete can negatively impact the environment. Additionally, the cost-benefit analysis of recycling versus reusing needs to be taken into account.

Reusing foundations on the other hand can bring about significant cost savings, whilst reducing the need for raw materials and cutting down on waste. However, there are potential barriers to foundation reuse that must be considered, such as record keeping, ensuring their structural integrity and meeting modern building requirements.

Design Engineering can optimise construction and homebuilding to reduce the overall environmental impact, allowing our industry to play a leading role in the transition to green economies that are getting closer and more integrated every day.Despite the magnitude of the challenges faced by this sector, there is massive opportunity for growth and innovation. SPEEDECK has been a leader in this domain, with solutions that promote sustainability while driving down costs and increasing efficiency.

We’re committed to developing new strategies and technologies that further this goal of building a better future through sustainable construction practices and processes. It is our hope that our efforts will help usher in an era when all buildings are designed, constructed, operated, reused and disposed of in an environmentally responsible way.

If you would like to discuss or clarify more on how to make your construction process environmentally sustainable with reduced costs and increased efficiency, please do get in touch – our experts at SPEEDECK will be more than happy to provide informative advice tailored specifically to your needs.