During the concept design phase, our analysis enabled us to highlight areas of concern and develop a targeted action plan.

Concept Design

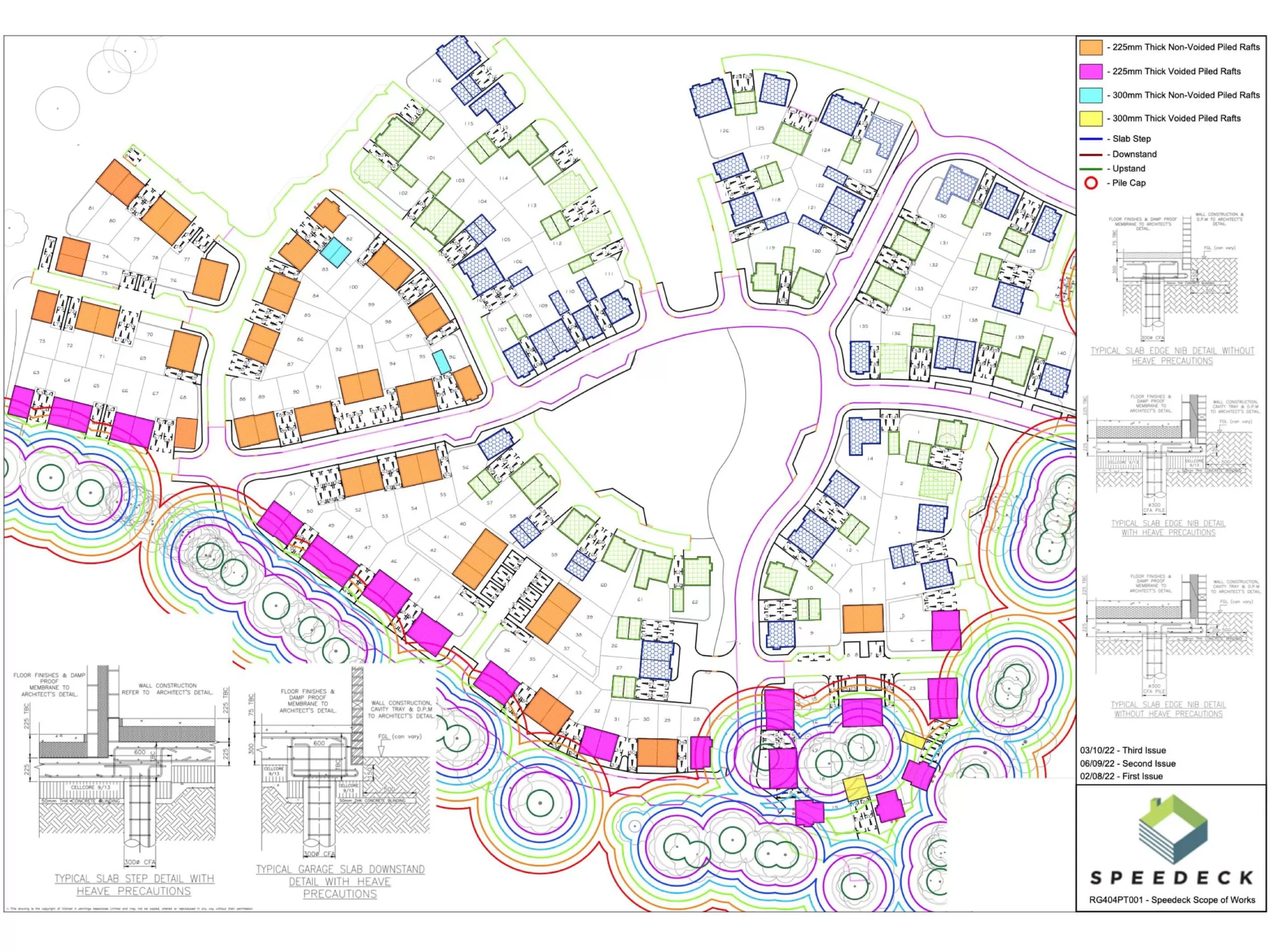

SPEEDECK identified that the standard deep strip scheme, although compliant with warranty providers, was not ideal for the site. We opted for a mix of voided and non-voided piled rafts, designed and implemented on a plot-by-plot basis.

This approach required a higher level of attention to detail and precision, yet allowed for optimal foundations across the entire site. It was also safer, more sustainable and superior to the deep strip method.

We were able to reduce the amount of Muck-away required to be taken off-site by opting for our foundation solution over the deep strip scheme. This resulted in considerable savings in terms of both time and money and enhanced the efficiency of the overall construction process.

By carrying out a heave assessment, we were able to minimise excavation time and reduce muck away further by identifying and mitigating against potential ground movement.

Trench shoring is often a critical part of construction; however, it’s also time-consuming, costly, and energy-intensive. By eliminating the need for this process, we improved efficiency, reduced costs and also lessened our environmental impact.

Moreover, our approach also mitigated the need for potential dewatering of the trenches, which can be a process leading to additional costs, potential delays in the construction timeline, and a significant amount of energy use. By avoiding dewatering, we further reduced our environmental footprint.

To ensure the foundations met warranty provider requirements, additional site investigations were carried out. These site investigations satisfied warranty provider requirements and helped provide an optimal scheme design.

Design Engineering

The design engineering phase built upon the solutions provided during the conception stage.

The SPEEDECK team liaised with the Warranty provider on the client’s behalf regarding heave, in order to provide further value to the scheme.

SPEEDECK’s Concrete Working Surface was utilised throughout, in lieu of granular piling mats. This generated significant savings in cost and time.

Construction

Our in-house teams handed over, implementing the various piled-raft foundation designs over 16 weeks, with the first tranche of 12 Units released after six weeks in difficult and wet weather.

This notable speed of construction allowed for units to be installed ahead of the Part L Regulations Deadline. The total Duration of Works inclusive of installation of Under-slab Drainage for 78nr Units + Garages (4,684m2) was 16 Weeks.

Our liaison with both the client and ground-worker allowed for effective communication regarding site preparation and build routes, resulting in further time savings for the programme.

We followed an internal inspection and testing plan to ensure sign-off by the building inspector and avoided any delays.

Our teams dedication and attention to detail allowed for a successful piling operation and handover of the project within an efficient timeframe, especially considering the challenging weather conditions.