Understanding Working Platforms

Concrete working surface as an engineered working platform.

A working platform is a temporarily strengthened structure consisting of a compacted layer of granular material, often a mix of natural high-strength aggregate or recycled concrete aggregate.

This material, typically ranging from 300mm to 800mm in thickness, is crucial for reducing the pressure on the underlying soil, providing the required stability for plant machinery such as cranes and piling rigs to operate effectively. These aggregates usually require transportation to the construction site.

Given their role in preventing potentially fatal accidents, working platforms must adhere to stringent health and safety standards. The Industry Body for the UK’s Foundation Contractors, the Federation of Piling Specialists (FPS), highlights that one-third of all reported Dangerous Occurrences in the field relate to working platform issues, and every incident posing a significant risk. An understanding of the safety standards guides the necessary evaluations for when and where working platforms are essential.

When are Working Platforms Required?

The Building Research Establishment’s document, BRE 470, details the necessary calculations to determine both the necessity and the specifications of a working platform. These consider the strength of the soil at ground level, compared to the loadings imparted by the construction plant.

Machinery on working platform.

Working platforms are typically required for most standard UK piling rigs and are essential on most ground types present in the southeast of England. These platforms must accommodate the bearing pressures from the plant equipment and be tailored to the specific ground conditions of the construction site.

According to BRE 470 and the Federation of Piling Specialists, a working platform must be designed by a professional with adequate geotechnical expertise. This ensures all critical factors—such as soil type, load requirements, environmental impact, and health and safety considerations—are considered during the design process.

Alternative Solutions to Engineered Working Platforms

Whilst traditional granular working platforms and piled rafts have been the standard in construction, alternative solutions are now changing the landscape:

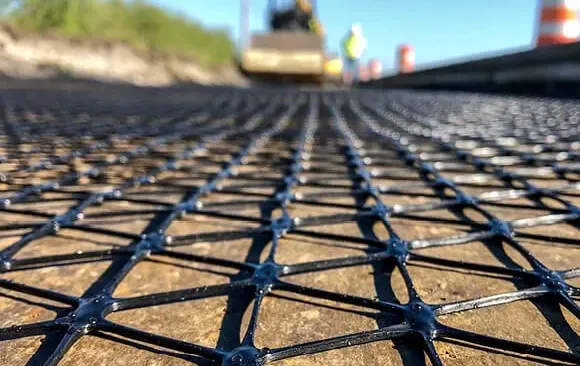

Geogrid Reinforcement

Geogrids are often incorporated into working platform designs to enhance load distribution and increase the bearing capacity of the subgrade, allowing for a thinner construction of the working platform.

BRE 470 acknowledges the use of geogrids with specific calculations that, while not always significantly reducing thickness, optimise the structural integrity and longevity of the platform.

Tensar® TriAx® (TX) Geogrids as part of working platforms.

Companies like Tensar specialise in bespoke geogrid solutions that are particularly effective on very soft ground, offering substantial improvements over traditional methods for platform design such as thinner platforms, lower costs and reduced importation of materials.

Tensar geogrids can be incorporated into the granular material, limiting surface deformation and settlements. Interlocking develops between the aggregate and the Tensar geogrid to prevent lateral movement of the granular material, increasing the strength of the platform.

Lightweight Piling Rigs

Lightweight piling rigs are designed to minimise ground pressure while still providing the stability and support needed for effective piling. The use of more lightweight piling rigs can reduce or even eliminate the requirement for a working platform altogether.

SPEEDECK’s Concrete Working Surface

SPEEDECK Foundations has developed a solution that utilises a Concrete Working Surface as a Working Platform. Our method of laying a 50mm thick concrete layer directly on the ground at formation level provides a suitable platform for lightweight piling rigs, and often exceeds traditional platform specifications with less material.

SPEEDECK’s concrete working surface as working platform.

This provides significant reductions in programme time and cost whilst minimising the need for extensive dig-outs and fill importation, thanks to the use of concrete instead of aggregates. This approach still ensures compliance with industry practice and has additional benefits in keeping the site conditions clean, dry and tidy, leading to a safer working environment whilst increasing the sustainability of the overall development.

Beyond the surface level, SPEEDECK employs advanced geotechnical analysis and design software to design pile dimensions and construction methods to the specific load requirements and soil conditions of each site. This optimisation process ensures that the piles are not oversized, sometimes enabling a more lightweight piling rig than would otherwise have been required. Find our more about Piling & Alternatives.

Case Study: Implementing a Working Platform in Challenging Conditions

In Moorgreen, Southampton, SPEEDECK successfully designed and constructed engineered foundations and effective working platforms for a residential scheme comprising 100 units. Facing challenges such as ground gas, site topography, and inefficient initial designs, SPEEDECK delivered innovative solutions that boosted design efficiency by 50%, and utilised cost-effective CFA piling for variable soil conditions.

The project was completed on time and within budget, despite adverse weather conditions, resulting in high-quality construction acknowledged by Building Control. Discover how our innovative working platform with piled rafts led to significant cost and time savings during construction for the client.

Cost-Efficiency and Sustainability for Working Platform Construction

While the initial cost of innovative materials like geogrids may be higher, the long-term savings in terms of reduced aggregate use, faster construction times, and lowering environmental emissions present a compelling case.

Using less material not only reduces costs but lessens the carbon footprint associated with material production and transportation. Lighter piling rigs, which are less disruptive and can operate on the SPEEDECK CWS without the need for additional reinforcement, further reduce the impact on the environment.

These solutions adhere to the strict health and safety standards set by UK construction regulations and EU directives and also align with the Construction (Design and Management) Regulations, which emphasise risk management from the outset.

Importance of Ground Investigation for Working Platforms Implementation

Successful implementation of working platforms begins with a thorough understanding of the ground conditions, with professional advice from geotechnical experts at the ground investigation stage. At SPEEDECK Foundations, we emphasise the importance of obtaining accurate and detailed ground information, especially for soft ground, to effectively design and construct working platforms.

Finished concrete working platform and piling at construction site.

To accurately assess the necessity for and design of working platforms, SPEEDECK relies on the California Bearing Ratio (CBR) test, subgrade strength, material choice, and other geotechnical evaluations to provide crucial data on the soil’s strength and bearing capacity. Our in-house team of geotechnical experts advise on specific test types and quantities to ensure comprehensive ground analysis, depending on the ground conditions.

Every construction site presents its unique challenges, but advancing technology, environmentally conscious practices and cutting-edge design are providing innovative solutions to challenges across our industry.

Engineered Working Platforms can provide optimal performance with adherence to all regulatory standards. Contact SPEEDECK today to learn more about our working platform solutions, including piled rafts, and how we can tailor our expertise to your construction needs.