During the concept design phase, several challenges were identified, and corresponding solutions were developed.

Concept Design

After an analysis of the consulting engineer’s initial design, it became clear that it was inefficient. This prompted SPEEDECK’s in-house structural team to create a new, bespoke solution that improved the design by approximately 50%.

To optimise the site’s topography, the project was split into two areas, and distinct solutions were developed for each section. This was driven by the previous activity on a part of the site which was used as a spoil tip during the construction of the M27 motorway.

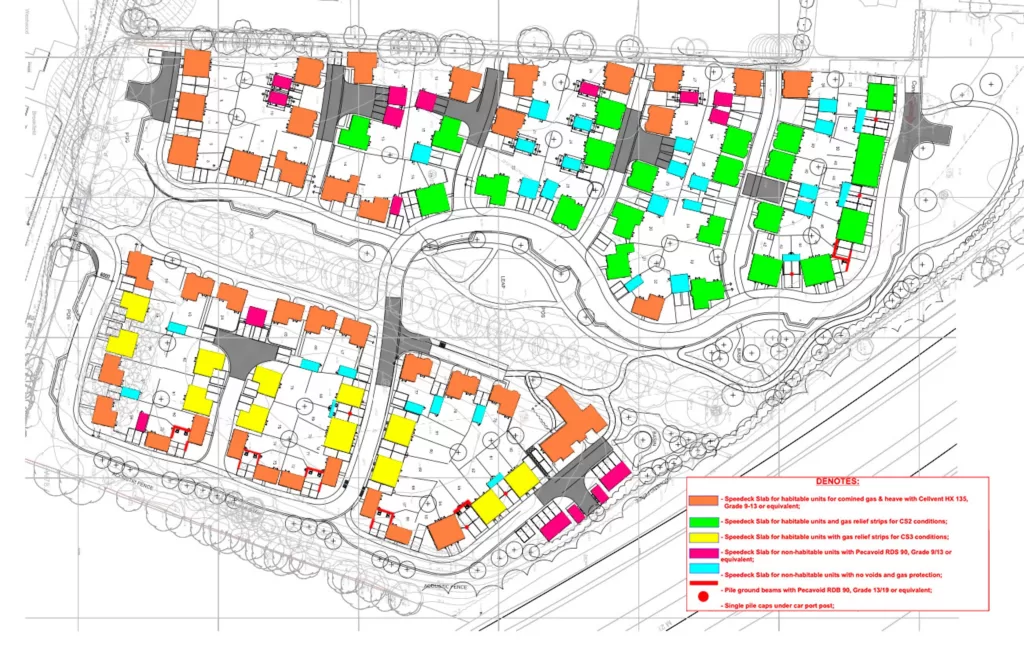

A comprehensive analysis of ground gas was conducted, and SPEEDECK improved upon the recommendations within the site investigation. SPEEDECK ensured the raft was sufficiently reinforced to act as a gas barrier, which minimised the additional components required.

Clay heave can be a costly problem to solve. SPEEDECK performed further testing on-site to determine the potential levels of clay heave and worked to minimise both the quantity and the thickness of the heave precautions required on-site. This resulted in cost savings in both the SPEEDECK foundation package and through the client having to transport less muck away off-site.

SPEEDECK divided the site into several areas, thus optimising the soil profile and design parameters across the site. Continuous Flight Auger Piling (CFA Piling) was a cost-effective solution for the variable soil conditions that could have made construction difficult. SPEEDECK managed to minimise the diameter and depth of the CFA piles, ensuring quicker construction times, less muck off-site and ultimately reducing costs for the client.

Design Engineering

The design engineering phase built upon the solutions provided during the conception stage.

The SPEEDECK design team worked through various approvals that the build required with other interested parties, such as consulting engineers and warranty providers.

Temporary works calculations were provided to demonstrate piling mats were not required, with a 50mm concrete working surface sufficient as a piling platform, generating significant savings with the cost and time of the build.

Calculations were provided for the relevant CS2 and CS3 gas site gas situations – approvals were obtained from the warranty provider for the client prior to commencement on site.

A heave report was provided to the warranty provider and approval was gained prior to commencement on site, realising the savings of mitigating extensive heave precautions.

A full drawing and calculation pack was produced for construction on-site, to simplify communication between the Pre-Construction and Construction teams.

Construction

Once on-site, the Pre-Construction team handed the project over to SPEEDECK’s experienced on-site construction team.

The information provided by the Design and Pre-Construction team ensured a smooth implementation process for the construction of the foundation system.

Our on-site construction team worked closely with the client’s team, our in-house design team and the warranty provider. Following the construction drawings exactly, the construction team were instrumental in delivering high-quality workmanship and obtained all the necessary sign-offs through the inspections with Building Control.