What is Radon Gas?

Radon is a naturally occurring radioactive gas that can seep into buildings from the ground. It is colourless, odourless, and tasteless, making it difficult to detect without proper testing.

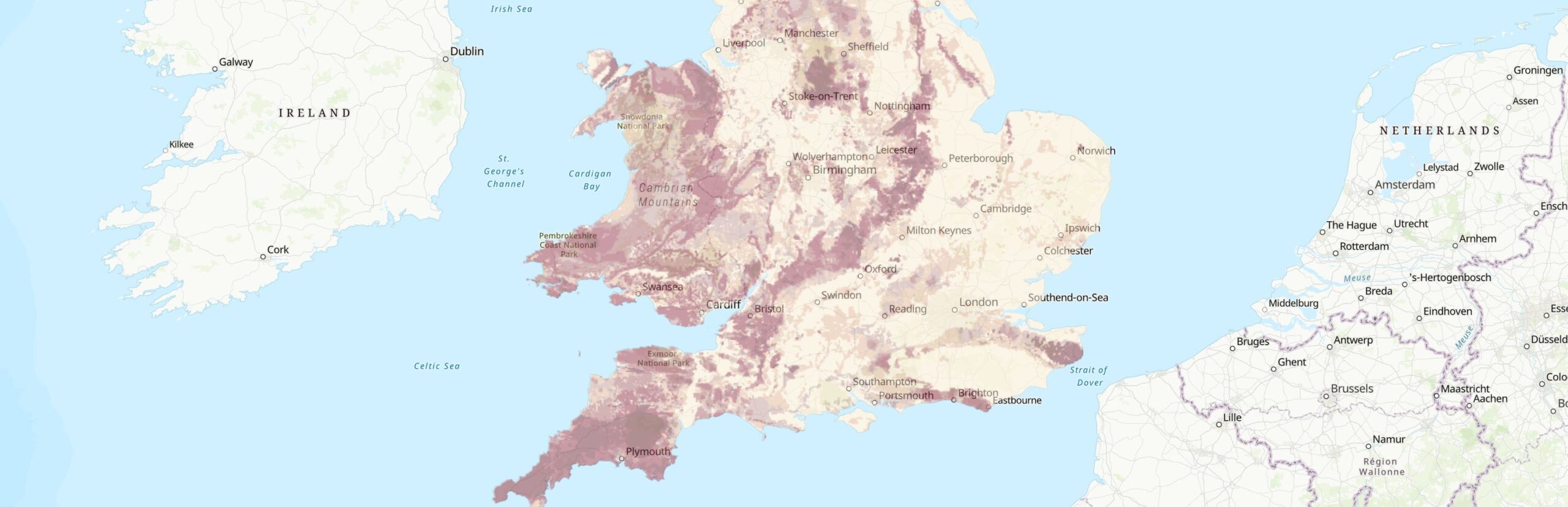

Radon Gas tends to be found mostly in South West England (Cornwall, Devon), Derbyshire, and parts of Wales and Scotland. However it can be found throughout the United Kingdom. Mapping published by the UK Health Security Agency (www.ukradon.org/information/ukmaps) shows radon affected areas and risk levels.

While all buildings contain radon, buildings in higher risk areas without appropriate mitigation’s included in the construction can accumulate radon to harmful levels, posing serious health risks.

How to deal with Radon Gas during construction?

Radon is a serious but manageable issue in new build developments. Proper foundation design, sealing, and ventilation strategies can effectively control radon levels, ensuring a safe indoor environment.

How does a piled slab foundation deal with Radon gas issues?

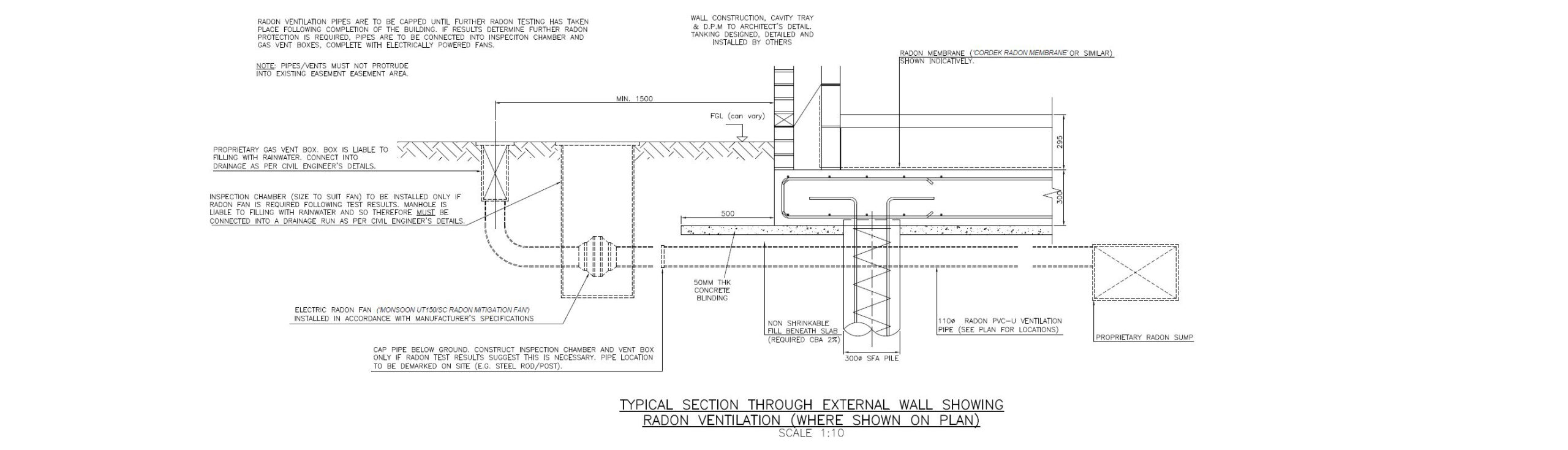

A piled slab foundation can effectively address Radon gas issues by incorporating specific mitigation measures designed to prevent gas ingress into the building. The key strategies include:

- Radon Barrier Membrane—To prevent radon from entering the structure, a gas-resistant membrane is installed on top of the slab. This is usually sufficient for lower levels of radon risk.

- Subfloor depressurisation system – Provision for future subfloor depressurisation can be integrated in areas of higher radon risk. While active depressurisation may not necessarily be required, sumps and pipework can be installed relatively simply beneath the raft slab so that depressurisation can be introduced at a later date.

- Adequate Joints & Penetration Sealing—To prevent leakage, all construction joints, service penetrations, and gaps must be well-sealed with gas-resistant materials.

By implementing these measures, a piled slab foundation can be designed to comply with radon protection requirements, ensuring a safe indoor environment.

Can I use Pile and Ground Beam foundations to deal with Radon Gas?

A piled slab foundation generally provides better Radon gas protection than a pile and ground beam solution because the ground beams create multiple joints and gaps where gas can enter. Membranes must be carefully lapped and sealed around beams and slab areas, increasing the risk of leaks and adding more materials and cost to the project. The space beneath the suspended floor (between the beams) can act as a void where radon can collect and seep through floor finishes if ventilation is inadequate. Over time, differential movement or poor sealing of joints may compromise radon protection, requiring inspections and potential repairs.

What is the best foundation solution for Radon Gas?

The optimal solution for radon gas mitigation in new foundations is a piled slab foundation with a radon-proof membrane, fully sealed around service penetrations, and joints. This design provides a continuous barrier, reducing gas pathways and minimising maintenance risks. Provision for future subfloor depressurisation can easily be introduced in higher risk areas. Compared to a pile and ground beam system requiring more complex sealing and ventilation, a piled slab foundation offers a simpler, more effective, and long-term radon mitigation solution that meets regulatory requirements.